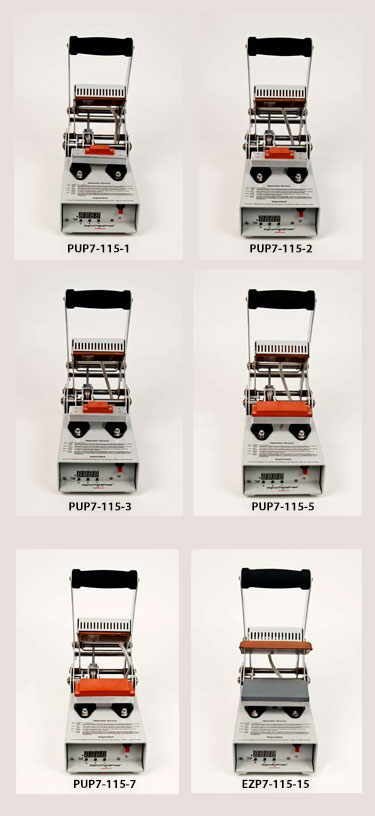

digital EzPress®, PopUpPress®

apply labels to fabric in 8 seconds, DiamondPress® 5 seconds

Dry cleaners, laundries, costume shops, hotels, casinos, nursing homes, institutions and uniform rental companies purchase our heat seal presses to permanently apply all manufacturers’ barcode and text labels to laundry and dry cleaning. Permanent clothing labels eliminate purchasing paper tags and the labor involved applying them and removing them. They also prevent lost garments when the paper tags fall off. Permanent labels eliminate the cost to replace lost garments. Our heat seal presses and permanent clothing labels will save you time and money while maintaining consistent pricing and finishing.

Our presses were designed with input from seven of the USA’s largest dry cleaners. They are the only heat seal presses designed for personal clothing with more features than other presses.

Features of our presses

Reliable computerized time and temperature control

The digital computer is calibrated to within 1 degree accuracy and will hold platen temperature to within 2% of your pre-set value.

Operator error alert & supervisor auditing

The digital computer will alert the operator and count the errors if applying a label when the platen is too hot or too cold or if lifting the handle before the pre-set application time has elapsed. Errors are counted and can be viewed by management for training and auditing purposes.

The time and temperature setup and calibration data is encrypted and can be changed only by someone who has the access code, without access, no unauthorized firmware changes can be made.

EzWizard™ Firmware with Hot Platen Supercharger™

EzWizard™ Firmware with Hot Platen Supercharger™ is calibrated to display the temperature with 1° accuracy and will hold platen temperature to within 2% of your pre-set value. It will automatically add additional seconds if the garment is cold or damp to make sure the glue is melted enough to permanently adhere the label to the garment for proper application.

QuickChange™ platens

Our QuickChange™ interchangeable high pressure mini platens come in 5 different sizes for EzPress® and PopUpPress® . Just lift one mini platen off and drop another mini platen on- no special tools required. The most popular is our mini-5 measuring 38mm x 95mm (1.5” x 3.75”). With this platen an operator can hide a label on the back of a care tag, hide a label inside a breast pocket jacket in addition to applying a label anywhere else on a garment. A mini-1 is the smallest platen 19mm x 38mm (.75” x 1.5”) which works great for heating a very small label and a small amount of fabric on an expensive garment or tie. Other sizes, mini-2 is 25mm x 38mm (1” x 1.5”), mini-3 is 25mm x 76 mm (1” x 3”) for a larger label, mini-4 is 38mm x 38mm (1.5” x 1.5”). DiamondPress® comes with a mini-5 lower platen.

One fixed size platen for larger applications is 76mm x 127mm (3” x 5”) available for EzPress® and PopUpPress® .

All of our heat seal presses are compact, light weight and are ideal for retail countertop use as they have a small footprint. EzPress®, PopUpPress® and DiamondPress® are only 279mm (11”) deep x 152mm (6”) wide x 228mm (8”) high, weigh only 6.4 kg (15 pounds). All three are energy efficient and do not have springs or thermostats.

Safety Certification

Our USA and International Safety Certifications:

TÜV SÜD America Inc (the world’s highest safety standards)

Our Certificate number is U8 11 11 78548 001

Tested according to CAN/CSA-E60335-2-44-01:2006, UL 60335-1:2003/A11:2004 /A1:2004 EN 60335-2-44:2002

CE, OSHA and UL approved

Proudly Made in the USA

Warranty

Our heat seal presses with EzWizard firmware have a two year warranty on parts and labor and Basic firmware ( a stripped down version) has a one year warranty on parts and labor. We have free technical support for the life of the equipment.

Factory setting temperature is 194° C (380° F) and standard time is 8 seconds for our mini versions for EzPress® and PopUpPress®. Our 76mm x 127mm (3”x5”) is factory set for temperature is 199° C (390° F) and 9 seconds. DiamondPress® factory settings are 350° and 5 seconds. With such low times and temperatures, you will not burn delicate fabric which is possible with competitors’ presses that require more than 205° C (400° F) and longer dwell times. Time and temperature can be adjusted from 177-215° C (350-420°) by management. Available in 115V. The ultimate heat seal machine.